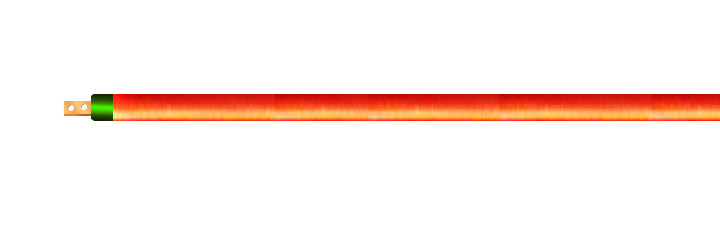

GI Copper Pipe with chemical Manufacturer

Veraizen Earthing are leading GI Copper Pipe with chemical manufacturers in Mumbai India. We provide GI Copper Pipe with chemical available in different grades. Our high-quality range of GI Copper Pipe with chemical are exclusively designed for steel factories, petrochemical industry, fire protection systems, chemical industries, shipping/shipment industries, etc. We offer GI Copper Pipe with chemical and more.

All GI Copper Pipe with chemical are designed and developed in accordance with IQS (International Quality Standards). Our GI Copper Pipe with chemical are made with precision using the best quality raw materials. We also offer customized GI Copper Pipe with chemical as per the customers requirement.

| GI Copper Pipe with chemical |

Specifications | Material: 48 1000, 2000 & 3000 35x6 76 1000, 2000 & 3000 50x6

|

Pipe Dia(mm)

|

48, 76. |

|

Length(mm)

|

1000, 2000, 3000.

|

|

Terminal

|

35x6, 50x6

|

GI Copper Pipe with chemical Manufacturer -

Veraizen Earthing provides high-quality GI Copper Pipe with chemical in major cities of India and also exports to more than 80 countries worldwide. All GI Copper Pipe with chemical are of International Quality Standards(IQS).

All GI Earthing Electrode

About GI Copper Pipe with chemical

GI Copper Pipe with chemical can withstand extreme high and low temperatures and pressures and can be exposed to the UV rays, temperature and oxygen of outside environments..Thanks to its excellent thermal conductivity, copper is the best material to exchange heat (or cold fluids). That’s why the most efficient radiant heating have circuits in copper pipe.

GI Copper Pipe with chemical Uses

GI Copper Pipe with chemical are widely used all over the world in different industries. Here are the top uses of GI Copper Pipe with chemical -

- Low cost and easily affordable: By zinc coating of the steel it becomes affordable to large scale business as well for household goods where the erosion is maintained and also protects the high-end machinery within affordable budget to get damage.

- Reliability: Galvanization helps the equipments to be more reliable, ductile and can withstand high voltage.

- Adaptability: Galvanization provides an alternative path in the electrical system to minimize the dangerous effect in the electrical system which happens at the time of lighting and unintentional contact with high voltage lines.

- Safety:Galvanized high-end machinery has a high level of safety procedure saving human life from electrical shocks and even secure the high-end machinery by providing a safe path of lighting and short circuit.

Get Quote

Get quote for your purchase requirements free of cost.

Send Enquiry